TOT快速連接器 美國(guó)進(jìn)口

產(chǎn)品品牌:Texas Oil Tools.

產(chǎn)品型號(hào):

規(guī) 格:

服 務(wù):由 鼎恒 發(fā)貨并提供售后服務(wù)。1年內(nèi)任何質(zhì)量問(wèn)題,包退換。

支付方式:支持網(wǎng)絡(luò)支付 | 公對(duì)公銀行轉(zhuǎn)賬

管匯

閥

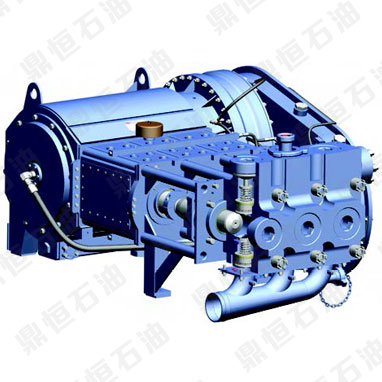

泵

防噴器

維護(hù)保養(yǎng)工具

儀器儀表

連續(xù)油管井下工具

其他產(chǎn)品

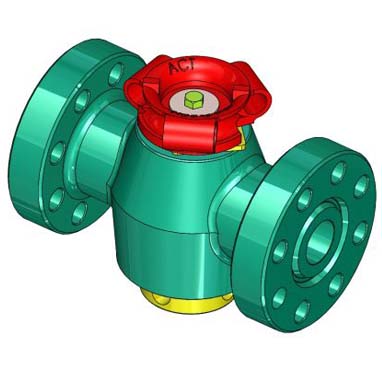

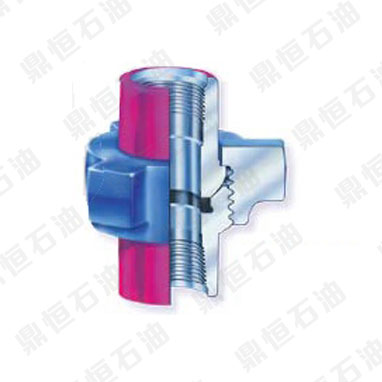

Quick Latches are used as a means to connect equipment together without a person standing under a suspended load. The rig up would consist of installing the pressure control equipment onto the wellhead and then installing the injector head. The injector frame would have the Stripper Packer mounted into the frame with a quick latch profile pointing down. The quick latch mechanism can be latched remotely without operation personnel working to help connect the last connection.

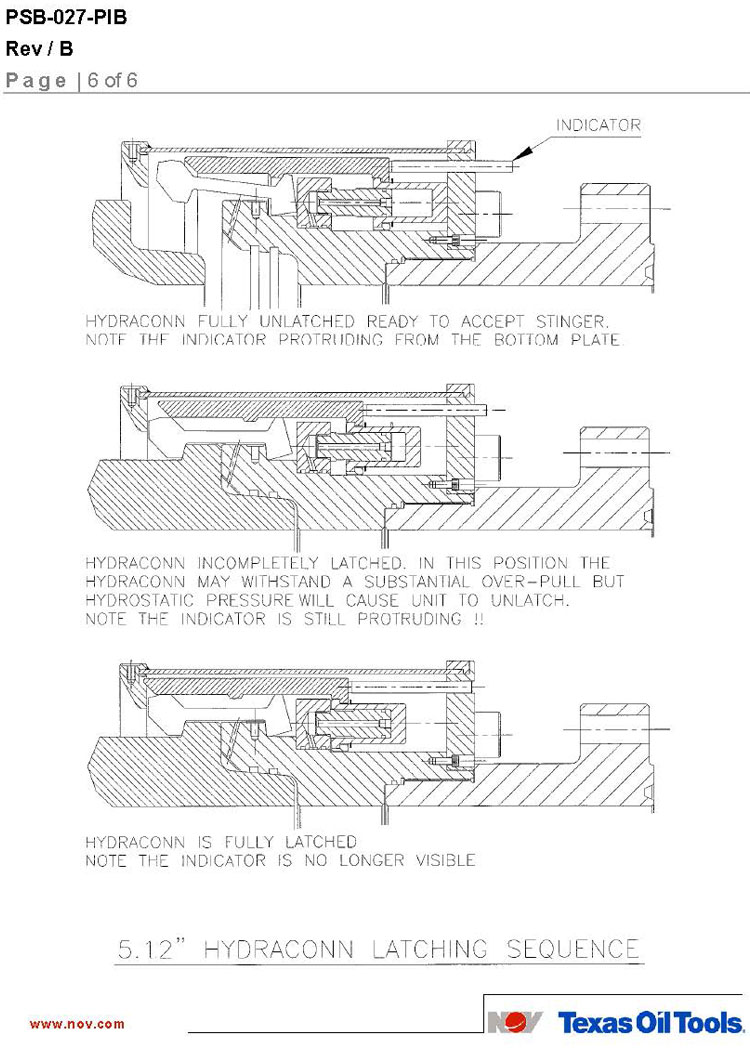

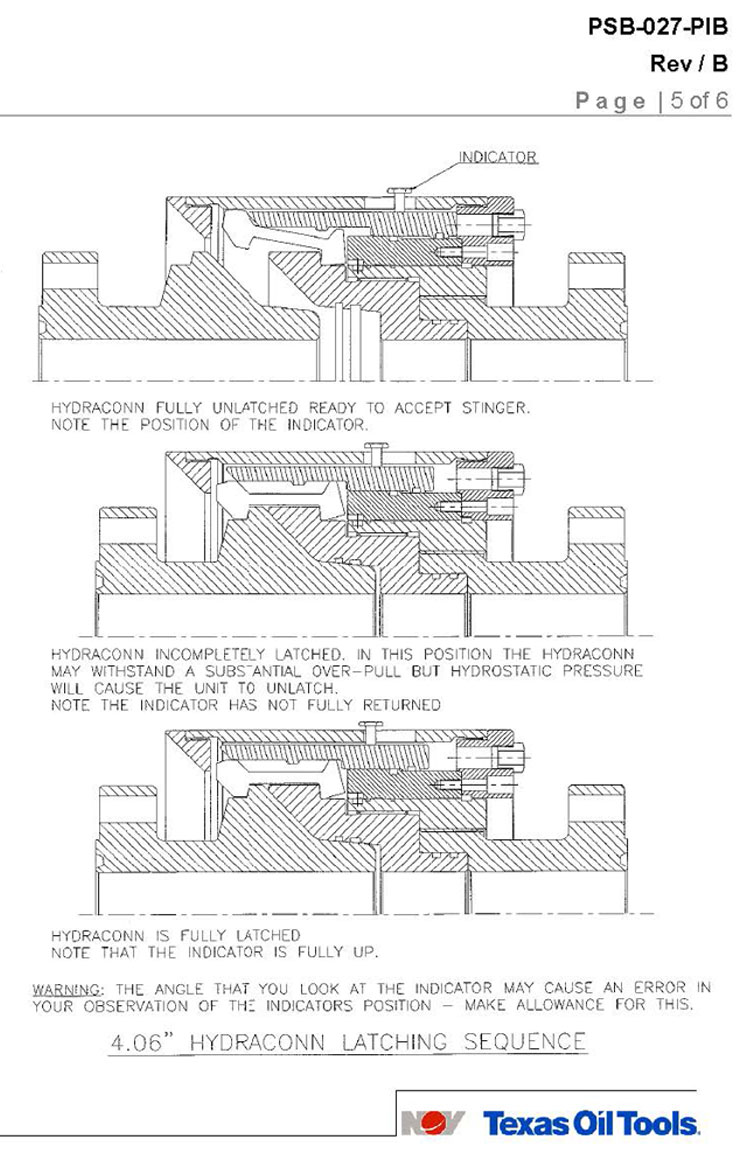

The TOT Hydraconn union is a rugged connector designed to permit a coil tubing injector assembly and the stripper packer to be stabbed and latched onto the top of coil tubing BOP’s, and have a funnel to guide the stabbing operation. It has a tapered seal bore which allows the connector to mate even when the injector is suspended at a slight angle. The Hydraconn is operated by a single hydraulic line which opens a series of latching dogs on the BOP mounted connector half to accept the stinger sub mounted on the bottom of the stripper packer. Once the two parts are stabbed together, the hydraulic pressure is vented and the spring loaded system forces the latch dogs closed, locking the Hydraconn together.

快速連接器是用來(lái)作為一種手段用于連接設(shè)備,解決了以往需要有人站在一個(gè)調(diào)載器下。該裝置包括安裝在井口上的壓力控制裝置,然后安裝噴射器頭。該噴油器框架將有一個(gè)防噴盒配合一個(gè)剖面向下的快速連接器安裝在框架上。快速連接器可以遠(yuǎn)程鎖存而無(wú)需操作人員幫助人工連接上一個(gè)連接。

TOT hydraconn 由壬是一個(gè)堅(jiān)固的連接器的設(shè)計(jì)允許連續(xù)油管注入頭總成和防噴盒串在一起,并鎖存到連續(xù)油管防噴器的頂部,有一個(gè)漏斗引導(dǎo)穿刺的操作。當(dāng)注入頭停止在一個(gè)很小的角度時(shí),它有一個(gè)錐形密封孔將與連接器相連。這個(gè)hydraconn是由一個(gè)液壓線操作,并在防噴器上打開(kāi)一系列的鎖孔,防噴器安裝的連接器一半用于接受安裝在防噴盒底部的插入短節(jié)。一旦將這2個(gè)部分被插入連接在一起,液壓就被貫通,然后管線運(yùn)載系統(tǒng)會(huì)將鎖孔關(guān)閉,將hydraconn鎖一起。